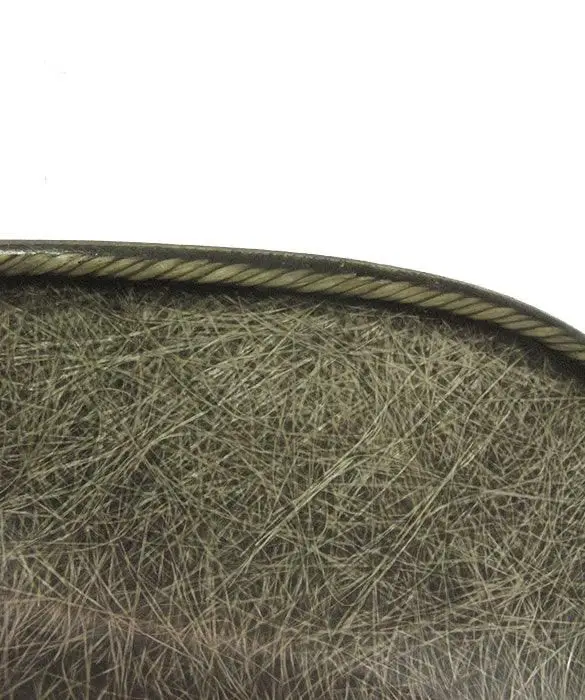

Fiberglass reinforced plastic rods (FRPR) are a type of building material that is often used in construction and engineering applications. FRPR rods are made from a composite of glass fibers and plastic fibers that are bonded together through a resin. FRP rods have many advantages over traditional materials, including being lighter, stronger, more durable, and more flexible.

Fiberglass reinforced plastic rods are a type of plastic that is made from strands of glass that are woven together to make a strong, durable material. Fiberglass reinforcement can add strength and durability to plastic materials, making them more resistant to damage from collisions or blows.

Fiberglass reinforced plastic rods are used in a variety of applications, including automotive parts, construction materials, and medical products. They are also used in products that need to resist high temperatures, such as ovens and furnaces. Fiberglass reinforced plastic rods have many uses because they are both strong and lightweight. This makes them ideal for use in products that need to be portable or movable.

Uses of Fiberglass Reinforced Plastic Rods

Fiberglass reinforced plastic rods are used in a variety of construction applications, including building frames, boats, and bridges. This article discusses some of the uses of fiberglass reinforced plastic rods and how they can be used to improve construction projects.

They have a variety of uses, most notably in the construction and manufacturing of sporting goods and equipment. In addition to their use in sporting goods, fiberglass reinforced plastic rods are also commonly used in the manufacturing of automobile parts, transportation equipment, and other construction works some of which are as follows:

- Roofing: Fiberglass rods are often used to reinforce roofs due to their durability and weather resistance.

- Garden furniture: Fiberglass rods make sturdy and durable garden furniture, chairs, and tables.

- Awnings: Awnings made from fiberglass reinforced plastic are strong and able to withstand high winds.

- Pool fencing: Fiberglass rods make sturdy pool fencing that is resistant to damage from pets and other debris.

Advantages of using fiberglass reinforced plastic rods

When it comes to creating strong and durable structures, nothing beats fiberglass reinforced plastic rods. Here are some of the main advantages of using these rods:

- They can support a lot of weight.

- They’re resistant to corrosion.

- They’re easy to assemble and disassemble.

- They’re affordable.

Disadvantages of using fiberglass reinforced plastic rods

There are a few disadvantages of using fiberglass reinforced plastic rods for construction. The most significant is that the material is very brittle and can easily break, which can lead to structural failure. Additionally, fiberglass reinforcements can cause excessive noise when the material is moved or stressed, and the material is also not as heat-resistant as other construction materials.

Costs associated with using fiberglass reinforced plastic rods

The cost of using fiberglass reinforced plastic rods can be high if the specifications for the product are not met. There are a few factors that can influence the price of a fiberglass reinforced plastic rod, such as the grade of the material, the diameter of the rod, and the length.

If a lower grade of fiberglass reinforced plastic rod is used, it may have lower strength and stiffness values. This would result in a higher cost per foot due to the need to purchase more material. A smaller diameter rod will also require more material to make up its weight, resulting in a higher cost per inch. Finally, a longer rod will require more materials to create its overall length, which will also lead to a higher cost.

If you’re interested in using fiberglass reinforced plastic rods for your next construction project, be sure to read our article on the benefits of these sturdy materials. Fiberglass reinforced plastic rods are strong and resistant to corrosion, making them a perfect choice for many applications. In addition, these rods come in a variety of sizes and shapes, so you’re sure to find the right option for your project

What are FRP rods?

Fiberglass Reinforced Plastic rods are made from a composite material that is strong and lightweight. They are often used in construction because they offer a number of benefits over traditional materials. FRP rods are:-Very flexible and able to withstand a lot of stress-Durable and able to last for long periods of time-Non-toxic and safe to use

What is the difference between FRP and GRP?

Fiberglass Reinforced Plastic (FRP) and Glass Reinforced Polymer (GRP) are two types of materials that are used in a lot of different applications. The main difference between FRP and GRP is that FRP is made from fiberglass reinforcement while GRP is made from plastic reinforcement. This means that FRP is stronger than GRP, but it also costs more to produce.

Is FRP stronger than steel?

It is often asked whether fiberglass reinforced plastic (FRP) is stronger than steel. The short answer is that it depends on the type of FRP and the conditions under which it is being tested. In general, though, FRP is considered to be a more durable material than steel. There are several reasons for this. First, FRP is able to withstand higher loads than steel without breaking. Second, FRP doesn’t corrode as quickly as steel, which means it can be used in areas where water or other liquids may be present. Finally, FRP is easier to fabricate and form into shapes than steel.

Can FRP be used outdoors?

FRP is a material that is made from plastic that has been reinforced with fiberglass. FRP is often used for outdoor applications because it is resistant to weathering and corrosion. This makes it a good choice for things like patio furniture, walkways, and decks. However, be aware that FRP is not always the best choice for outdoor use. For example, FRP can be brittle and is not as strong as traditional materials when it comes to resisting cracking or breaking. So, be sure to test an idea or project with FRP before you start construction to make sure it will hold up in the long run.

Does fiberglass last longer than steel?

Steel and fiberglass have been used in construction for centuries, but which material lasts longer? The answer may surprise you. Steel is made from a variety of metals that are heated until they reach a certain temperature.

This process creates a metal alloy that is strong and durable. However, steel corrodes over time. Steel also rusts, which leaves it vulnerable to water damage.

Fiberglass, on the other hand, is made from glass fibers that are bonded together with a special resin. This makes fiberglass resistant to corrosion, rust, and water damage. In fact, fiberglass can last up to 10 times longer than steel!

How much pressure can fiberglass withstand?

Fiberglass reinforced plastic rods are made from multiple layers of fiberglass that are bonded together with a resin. The resin creates a tough and durable material that can withstand a lot of pressure. In fact, fiberglass reinforced plastic rods can withstand up to 6,000 psi (45 MPa). This means that they can hold up to a lot of weight and resist breaking or cracking.

.